Smart textiles have been rapidly introduced into the military industry due to the increased demand for supportive and performance-enhancing clothes. The goal of smart textiles is to minimise the weight of battery packs, electronic devices, and connectors, among other things.

It is important to highlight several approaches at various levels of textile integration, all of which share the same goal: to construct the most efficient and high-performance electronic-textile structure possible. The raw materials used play a crucial influence in the procedure used to create fibres, yarns, or textiles with electrical or sensing capabilities. Wearable systems are becoming more possible because to developments in textile technologies, new materials, nanotechnology, and tiny electronics; however, the last critical component for user adoption of wearable devices is the fit comfort.

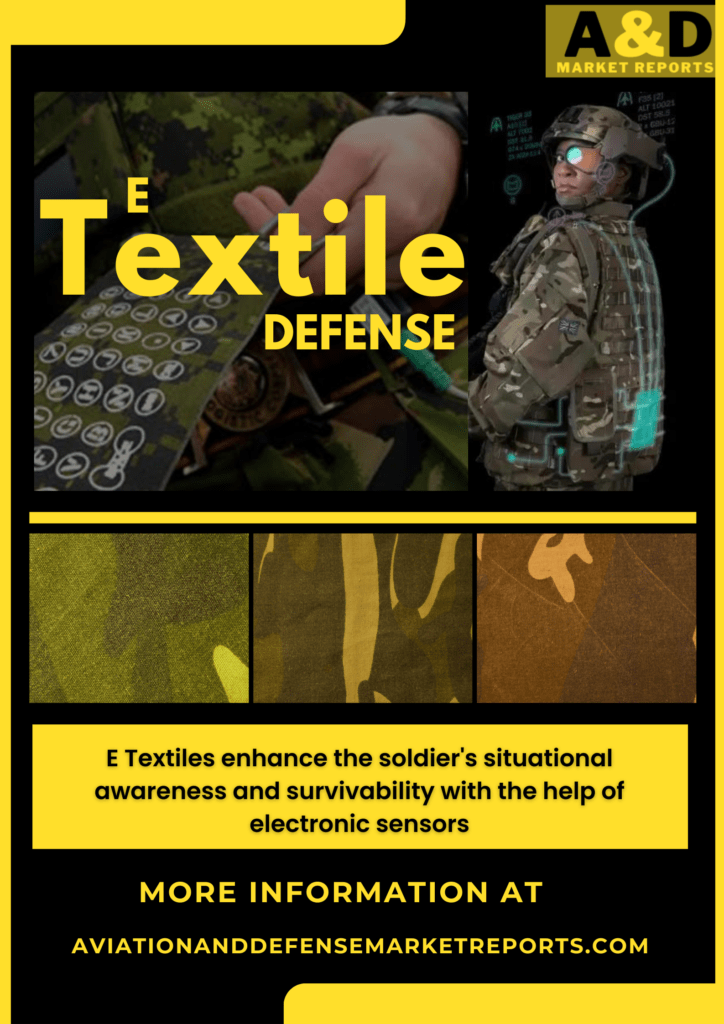

Overall, the goal is to find appropriate materials that can interface with textile structures and add electrical/sensing elements without compromising the fabric’s natural attributes, such as flexibility, wearability, comfort, and washability. To put it another way, e-textiles are textiles that have components that allow them to function as part of an electronic system. E-textiles can track feelings, transmit data, and receive signals from other parts of the electronic system, among other things. E-textiles come in a variety of shapes and sizes, and they can be tailored and altered for a variety of uses. Continue reading to learn more about the many kinds of e-textiles.

E-TEXTILES WITH EMBEDDED COMPONENTS

One of the two major types of e-textiles is embedded e-textiles. They have recently gained in popularity over the other type of e-textile, laminated e-textiles. Electronic components are woven into the fabric of embedded e-textiles. A pair of gloves with conductive yarn woven into the fabric for heating reasons is an example of an embedded e-textile. Embedded e-textiles are more suitable for everyday usage than laminated e-textiles because they don’t have bulky sensors. The power and complexity of the electronic systems that can be embedded in embedded e-textiles are restricted. As sensors and circuitry become smaller and thinner, this is likely to alter in the near future.

E-TEXTILES WITH LAMINATION

In recent years, laminated e-textiles have garnered less attention than embedded e-textiles. This is likely due to the fact that laminated e-textiles are thicker, but embedded e-textiles are more appealing visually. Electronic components are not woven into the fabric of laminated e-textiles. Rather, circuitry and sensors are manufactured separately and then affixed to the cloth. A tank top for soldiers with sewn-in sensors that monitor vital signs during missions is an example of a laminated e-textile. Laminated e-textiles can currently accommodate more complicated sensors and electronics than embedded e-textiles. The development of advanced technologies such as fabric circuit boards, on the other hand, may close the gap between the capabilities of embedded and laminated e-textiles.

Smart Shirt

The wearable motherboard, also known as the Smart Shirt, is a platform that enables fusion between electronics and fabrics. The smart shirt is made out of a basic fabric such as cotton or polyester, which is then embedded with sensors and connective technology to create a flexible and wearable system. The databuses and information infrastructure are formed by the conducting yarns embedded into the fabric. The information (signals) are routed through specified channels in the fabric using an interconnection method, resulting in a motherboard that serves as a flexible and wearable framework into which sensors and gadgets can be plugged into. The signals from the sensors are routed to the multi-function processor/controller via the flexible data bus built into the structure. With optical and conductive fibres woven into the garment, the T-shirt works like a computer. It can track vital signs, such as heart rate and respiration, and can be used by security agents, military people, and astronauts. One of the most difficult tasks for medical personnel is detecting the soldier’s wound and establishing his vital signs among the turmoil of the battlefield. A uniform that monitors a soldier’s vital signs can send the exact location of a wound to the battlefield via wireless, saving important time and lives. The life shirt system is a comfortable garment that can be worn under conventional uniform and can monitor over 40 bodily indications such as respiration rate, ventilation, swallow counts, arterial pulse wave, and heart rate automatically and constantly.

SHIELD AGAINST CHEMICAL AGENTS

Toxic chemicals have both emotional and deadly consequences, which we must be aware of. These are nefarious weapons of mass devastation. For protection, there are primary and vital gadgets. Toxic species are filtered out and deactivated using oro-nasal and full-face respirators. The agent vapour is absorbed by activated carbon on a textile substrate in these respirators. The activated carbon has a pore structure that allows for a large surface area, allowing for the absorption of a wide range of hazardous gases.

There is no doubt that E Textiles in defense enhances crew survivability and increases the operational efficiency. With rapid development in semiconductor and textile technology, the capability of E textile will continue to evolve and possess advanced features.